What is a Smart Cleanroom Garment?

Cleanrooms are controlled environments with low levels of pollutants, such as dust, airborne microbes, and chemical vapors. These environments are commonly found in industries like semiconductor manufacturing, pharmaceuticals, and biotechnology, where even tiny contaminants can adversely affect the production process.

A “smart cleanroom garment” or “RFID-enabled cleanroom garment” refers to a cleanroom garment that incorporates a microchip or RFID (Radio-Frequency Identification) chip for tracking and monitoring purposes. Cleanroom garments, such as suits, coveralls are worn by personnel working in cleanrooms to minimize the introduction of contaminants. By incorporating RFID or microchip technology into these garments, it becomes possible to track the movement of personnel within the cleanroom facility. This tracking system helps in ensuring that the proper procedures are followed, and it provides a record of personnel movements for quality control and compliance purposes.

The microchip or RFID tag can store information such as the employee’s identification, entry and exit times, and possibly other relevant data. This technology enhances the overall control and monitoring of cleanroom environments, contributing to the maintenance of the required cleanliness and adherence to strict protocols.

Gaible, established in 2008 and headquartered in Shanghai, China, is at the forefront of smart cleanroom management technology. It has self researched and developed smart cleanroom garment combines with smart access control system, cleaning and sterilization management recorders, etc.

Gaible’s Main Smart Cleanroom Products:

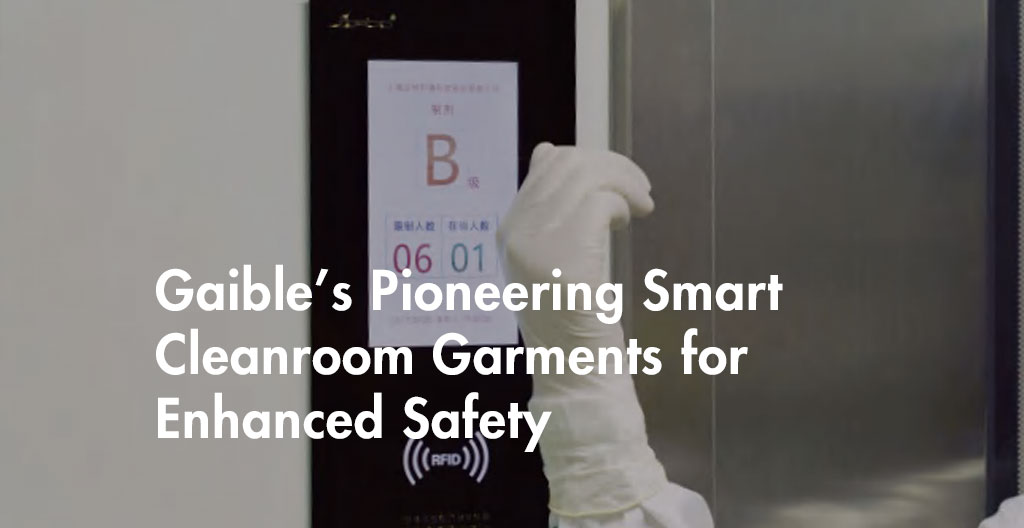

The smart access control system and smart cleanroom garments Launched by Gaible is a comprehensive access control management system tailored for pharmaceutical enterprises. The access control areas managed by the system include general office areas, living areas, production non-cleaning areas, CNC, and Grade B, C, and D clean areas. it covers the unified management functions of people and logistics channels.

The system applies a variety of identification methods such as traditional passwords employee badge access cards, cleanroom suits implanted with electronic chips, and fingerprint or iris bio metrics. In addition, according, to the current situation of pharmaceutical enterprises, specific access authority strategies are formulated for various types of personnel, implementing one-stop three-dimensional protection comprehensive solution of access control for pharmaceutical enterprises and meeting their exclusive unified access control management needs. lt fills the gap in the international market and has obtained international intellectual property right protection and related authorization.

Smart Cleanroom Suit Management System

Smart cleanroom suit management system is an integrated management system of identity recognition and digital signature based on RFlD technology. The system uses RFID (Radio Frequency Identification) electronic tags or other identification methods implanted in the cleanroom suits to manage the access rights of the staff to the clean area, the use rights of the production equipment, and the service life, cleaning and sterilization process management of the cleanroom suits itself

The system automatically keeps a record of each RFID identification and uploads it to the database, which is convenient for users to flexibly search the entry and exit records, production equipment usage records, and cleaning and sterilization records of cleanroom suits.

The system consists of software and hardware. They are independently developed by Gaible, and have independent intellectual property rights.

Gaible’s RFID technology was self researched and development with several advantages:

1.Robust Anti-Interference Capability

2. Ample Data Storage

3.Dynamic Operation

4.Extended Lifespan

5.Simultaneous Multi-Chip Data Reading

6.High-Level Security Measures

7.Rapid recognition

Smart cleanroom suits cleaning and sterilization management recorder

Introduction

TF-C2C3 Handheld terminal for management of cleanroom clothes is an industrial PDA with an external RFID module, PDA handheld terminal scanning can realize the effective collection, rapid identification, accurate verification, and management integration of high-precision chip data, Configure functions according to the usage scenarios to make management more convenient and easier to use.

Functions

- Support online and offline identification of chip information

- traceable warning settings for the service life and scrapping of cleanroom clothes

- Fast chip reading

- 4. Service life management of cleaning suits

- Water proof, dust proof and non-slip

lris+ RFlD dual-module access control machine

TF-C5A3 is a high-performance iris smart access control manager for clean area designed in accordance with industrial-grade technical requirements. It has built-in multi-tasking system and supports multiple authorization methods and real-time control of the number of personnel in the clean area. TF-C5A3series can work offline and online.

Functions

1.Personnel access authority management of clean areas

2.Real-time control of the number of personnel in clean areas

3.Access control responding to cleanroom suit cleaning and sterilization status

4.Access control responding to the service life ofcleanroom suits

5.Support installation and use in clean areas, even in Grade B+A clean areas

6.Electric lock control interface supports normally opening and closing options

7.Support manual door opening with button signal input8.Support iris + RFlD cleanroom suit dual verification mode

Here are the key benefits of Gaible’s smart cleanroom garment.

Click Here to Explore Our Cleanroom Products !

- Cleanroom Garment Cleaning Status Record

Gaible cleanroom garments are high quality reusable cleanroom garments which can resistant to repeatedly washing and sterilizing by moist-heat high temperature. It is critical to clean the garments regularly and keep the cleaning record.

The traditional recording of cleaning and sterilization status requires manual recording and integration, which not only causes a waste of human resources, but also posed to the risk of errors and deviations in the recorded data and lacks data accuracy. While using Gaible Smart cleanroom garments, combined with smart suits cleaning and sterilization management recorder, can manage the cleaning work signature, cleaning and sterilization status, and service life of clean clothes, as well as query the cleaning and sterilization status of clean clothes, and form reports in the background to monitor the clean clothes. It can realize full life cycle management, greatly save labor costs, and achieve systematic and data-based management.

- Enhanced Security

RFID technology enhances security by providing a controlled access system. Only personnel wearing the authorized RFID-enabled cleanroom garments can access specific areas within the cleanroom facility, helping to prevent unauthorized entry.

Gaible has developed a series of different authority and traceability methods of personnel management, such as iris identification, finger print, password and card identification based on different requirements in each grades of clean area.

RFID-enabled cleanroom garments contain unique identification information. Access to different areas within the cleanroom facility can be restricted based on this identification. The RFID system ensures that only individuals wearing authorized garments with valid RFID tags can gain access to specific zones.

The RFID-controlled access system helps prevent unauthorized personnel from entering restricted or critical areas. This is crucial in cleanroom environments where maintaining a controlled and contamination-free space is paramount for the integrity of processes and products.

- Compliance Monitoring

The RFID system provides real-time monitoring of personnel movements. Cleanroom managers can instantly identify any anomalies or unauthorized access attempts, allowing for immediate response and investigation.

The electronic chip built can write the information of the staff and the information of the clean clothes. By scanning the electronic chip, the access control system can automatically identify whether the employees have access rights and whether the clean clothes have been cleaned and sterilized, achieving intelligent management. While ensuring personnel management authority, it also avoids manual entry and exit record deviations and data errors.

The data collected from RFID-enabled garments can be used for analytics and insights. Cleanroom managers can analyze patterns, identify trends, and make data-driven decisions to improve overall operations and efficiency.

- Contact free Access

Gaible has developed a series of different authority and traceability methods of personnel management. Gaible Contact-free access control with iris recognition in cleanroom environments offers several advantages, particularly in terms of security, hygiene, and convenience.

Iris recognition is known for its high accuracy in identifying individuals. The unique patterns in the iris provide a highly secure means of authentication, reducing the risk of unauthorized access.

The contact-free nature of iris recognition is crucial in cleanroom environments where minimizing physical contact is essential to prevent contamination. Users can gain access without touching any surfaces, reducing the risk of transferring contaminants.

Iris recognition systems can be designed to be easily cleaned and resistant to environmental factors. This ensures that the system remains hygienic and compliant with cleanroom standards, where strict cleanliness and contamination control are paramount.

- Efficient Workflow

RFID-enabled cleanroom garments can contribute to optimizing workflow and process efficiency. By monitoring personnel movements, cleanroom managers can identify potential bottlenecks or areas of improvement in the production or research processes.

- Error Reduction

The automated tracking provided by the embedded chips helps reduce manual errors in record-keeping. This can be particularly important in environments where precise documentation of personnel activities and movements is critical for quality control and regulatory compliance.

- Quick Response to Contamination Events

In the event of a contamination incident, RFID technology allows for quick identification of personnel who may have been in the affected area. This rapid response can help mitigate potential risks and prevent further contamination.

- Comfort and Durability

Gaible’S RFID chip is made of silicon in the exterior, it is normally embedded in the cuff of the garment. It is soft and comfortable to embed in the garments. Besides, it can also withstand repeatedly washing and sterilization with the same life cycles as cleanroom garments.

Gaible has obtained dozens of international invention patents, software copyrights, utility model patents, design patents, and other intellectual property rights certificates, Gaible meets the needs of GMP production management with its innovative and unique design concepts and professional leading product technology. It successfully responds to the intelligent era of industrial information 4.0 and contributes to the development of the industry.

As a pioneer and leader in smart access control systems and smart cleanroom garments, the most significant advantage of the system lies in the powerful digital processing and a complete network transmission function in the background.

Gaible’s smart cleanroom garments, in conjunction with iris RFID dual-module intelligent access control machines, can achieve functions such as personnel access management in clean areas, real-time display of on-duty personnel information in clean areas, real-time monitoring of the number of personnel in clean areas, and query of personnel access records in clean areas. Compared to the mainly manual record-keeping and inefficient process of managing the entry and exit of individuals wearing regular cleanroom garments, the management of smart cleanroom garments is more information-oriented and intelligent.

The integration of cleanroom smart technologies into cleanroom garments aims to enhance efficiency, security, and compliance within cleanroom environments, where maintaining a controlled and contamination-free atmosphere is critical for various industries, including pharmaceuticals, semiconductor manufacturing, and biotechnology.

0 Comments